Time Delay Relays: Working, Types, and Applications

Introduction

Relays are fundamental components in electrical and electronic control systems. In modern electrical and automation systems, timing control is often as important as switching control. While conventional relays provide immediate switching, many processes require a controlled delay—for example, starting motors in sequence, delaying lights, or keeping equipment running briefly after power is removed. This is where time delay relays (TDRs) play a crucial role.

What is a Time Delay Relay?

A time delay relay is a relay that does not operate immediately when the input signal is applied or removed. Instead, it waits for a pre-determined amount of time before switching its contacts. The delay can be set anywhere from milliseconds to hours, depending on the relay design.

These relays provide precise timing functions, allowing for better control in circuits that require sequential switching, delayed start, or delayed stop operations.

Working Principle of Time Delay Relays

A time delay relay operates on the same fundamental idea as a standard relay: an input signal energizes a coil, which in turn changes the state of contacts (open or close). The difference lies in the introduction of a time element—the contacts do not switch immediately, but only after a preset delay period.

The working can be broken down into two main stages:

-

Input Stage (Coil Energization or De-energization):

-

When voltage is applied (or removed) to the relay’s coil, it does not instantly actuate the contacts.

-

Instead, a timing mechanism (electromechanical or electronic) begins counting the preset delay.

-

-

Output Stage (Contact Switching):

-

After the set time interval expires, the relay contacts change state (from NO → NC or NC → NO, depending on configuration).

-

The exact moment of switching depends on the type of relay:

-

ON-Delay Relay: Contacts change state only after the coil is energized for the set time.

-

OFF-Delay Relay: Contacts remain in their energized state for the preset time after the coil is de-energized.

-

-

Types of Time Delay Relays

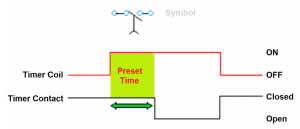

1. ON-Delay Relay

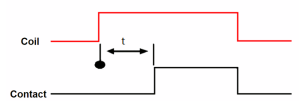

This is also known as “On Delay” or “ To work with delay”. In these types of relays the contacts change position after a time since the timer coil began to activate (energize).

- Once the current reaches the timer coil, after a time “t”, the contacts change position, that is, the ones that were open close and the closed contacts open (working state).

- They will stay that way as long as the coil is powered.

- They will return to their initial state (at rest) when no current reaches the timing relay coil. If the power supply to the coil is cut, at that moment, the contacts return to their resting state automatically.

- The time is regulated by using a rotary knob built into the timer itself. The pre-set time can be from as few as milliseconds to hours and even days. But it is usually set in seconds and minutes in industrial control systems.

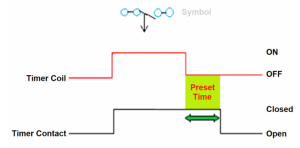

2. OFF-Delay Relay

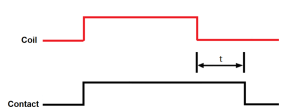

It is also known as “sleep delay” or “Off Delay”.

- In these type of relays, the contacts change position as soon as the current reaches the coil. As soon as the coil is deactivated, the deactivation time “t” starts to lapse, so that they start to return to their initial state (rest).

- The “t” represents the time between the moment the coil is disconnected and the moment the contacts change their positions.

- As long as the coil is energized, the contacts will be in the working position.

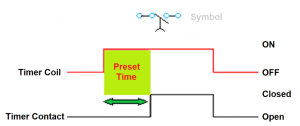

3. Normally Open Timed Closed (NOTC)

Normally open, (instant open), time delay close (NOTC) upon energizing. This type of contact is normally open when the coil is unpowered (de-energized). The contact is closed by the application of power to the relay coil, but only after the coil has been continuously powered for the specified amount of time.

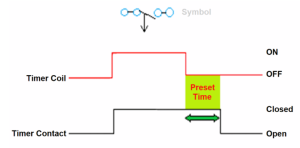

4. Normally Open Timed Open (NOTO)

Normally open, (instant close on energization), time delay open (NOTO) after de-energization. Like the NOTC contact, this type of contact is normally open when the coil is unpowered (de-energized), and closed by the application of power to the relay coil.

However, unlike the NOTC contact, the timing action occurs upon de-energization of the coil rather than upon energization. Because the delay occurs in the direction of coil de-energization, this type of contact is alternatively known as a normally-open, off-delay.

5. Normally Closed Timed Open (NCTO)

Normally closed, (instant close), time delay open (NCTO) upon energization. In this type, contact is normally closed when the coil is unpowered (de-energized). The contact is opened with the application of power to the relay coil, but only after the coil has been continuously powered for the specified amount of time.

6. Normally Closed Time Closed (NCTC)

This type of contact is normally closed when the coil is unpowered (de-energized), and opened by the application of power to the relay coil.

However, unlike the NCTO contact, the timing action occurs upon de-energization of the coil rather than upon energization. Because the delay occurs in the direction of coil de-energization, this type of contact is alternatively known as a normally-closed, off-delay.

Applications of Time Delay Relays

-

Motor Control

-

Prevents motors from starting simultaneously, avoiding inrush current.

-

Sequentially starts multiple motors in industrial setups.

-

-

Lighting Control

-

Delays turning lights on or off in corridors, staircases, or security systems.

-

-

Heating and Cooling Systems

-

Provides time delays to prevent short cycling of compressors and fans.

-

-

Safety Systems

-

Ensures equipment shuts down in a controlled sequence.

-

-

Industrial Automation

-

Used in conveyor systems, packaging machines, and process control where timed sequencing is essential.

-

Advantages of Time Delay Relays

-

Simple and cost-effective timing solution.

-

Wide range of delay settings (from milliseconds to hours).

-

Improves safety and sequencing in electrical systems.

-

Available in both electromechanical and solid-state designs.

Conclusion

Time delay relays are vital components in modern control systems, providing precise timing control for a variety of applications. From industrial automation to household devices, they ensure smooth operation, safety, and efficiency by managing the timing of electrical circuits. As technology advances, electronic time delay relays are becoming more popular due to their accuracy, durability, and programmability.