PCBWay OEM Services – The One Stop Solution

What is OEM ?

OEM stands for Original Equipment Manufacturer. Basically it is a company which manufactures products, which are then used as components in the products of another company, that sells the finished goods to the final consumer.

An OEM undertakes contract manufacturing of components, that allows the other PCB manufacturing company to focus on its core capabilities and processes. The OEM PCB manufacturer always ensures that the final product lives up to its reputation as well as cost effective. By using the OEM service, the PCB manufacturing companies ensure that they do not have to incur increased cost or increase capacity in areas that are not their forte.

PCBWay OEM Service

With an experience of more than a decade in the field of PCB prototype and fabrication, PCBWay is one of the most experienced and trusted PCB manufacturing company based in China.

One Stop Solution

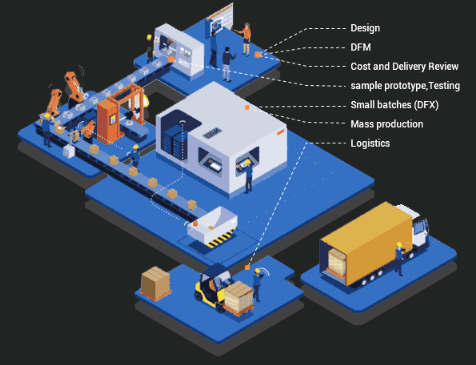

PCBWay has now introduced a complete contract manufacturing service (One Stop Solution) know as OEM service with its strategic alliance partners. This service includes, product design, product development, engineering validation, PCBA (Printed Circuit Board Assembly) manufacturing service as well as supply chain management. Which means it is now working closely with manufacturers throughout the whole process to ensure the reduced cost while maintaining the performance. Lower the cost of the product, higher is the demand for it as more people can afford the product at cheaper rate.

In this rapid evolving market, PCBWay makes itself standout by providing one-stop shop solutions to simplify and manage all the complexity at one stop. Starting from early design concept to packaging fully assembled devices that are ready for shipment, PCBWay provides all the services.

It enables the factories to produce the best quality products by using high mix / low volume, quick turn prototyping and NPI services with no limits on quantity. Their operational knowledge across numerous industries permits consumers to reduce working capital in a number of ways. PCBWay excels at taking conceptual designs and transforming them into tangible quality products. It also simplifies the complex process of component sourcing.

Project Review (DFM)

- Set up a special group

- Reliability analysis

- Equipment analysis

- Process analysis

- Develop quality control

- Material quality control

- Sign OEM agreement

- Sign non-disclosure agreement

Project Approval

- PCB Supply Chain Management

- Electronic Components Supply Chain Management

- Mold Supply Chain Management

- Injection Molding Supply Chain Management

- Structural Parts Supply Chain Management

- Excipient Supply Chain Management

- Sheet Metal Supply Chain Management

- Hardware Supply Chain Management

- Packaging material supply chain management

Prototype

- PCBA functional verification

- Material verification

- Part verification

- Product certification

- Mold review, design, acceptance, mold testing, PCBA functional testing

- Part confirmation, process evaluation and formulation, component production and procurement.

Small batches (DFX)

- System assembly

- Box build

- Stencil

- POP process

- Burn-in

- Packaging design and retail packaging

- TQM- total quality management

- Electrical/Mechanical engineering support

- Testing

- Supply chain management

- Documentation support

Bulk production

- System assembly

- Box build

- Stencil

- POP process

- Burn-in

- Packaging design and retail packaging

- TQM- total quality management

- Electrical/Mechanical engineering support

- Testing

- Supply chain management

- Documentation support

Logistics

OEM Industrial Chain Ecological Panorama

PCBWay OEM helps the factories to produce according to their customers need. It is using the Internet, Internet of Things, and cloud technology to transform the entire value chain of the electronics manufacturing industry. It also helps the factories to realize centralized order input, provides digital engineering technical services, and conducts highly digital workshops.

To expand the upstream and downstream high-quality production capacity of the electronics manufacturing industry rapidly, PCBWay adopts the “1+N” innovative model of self-operated factories along with the collaborative factories.

PCBWay OEM helps the whole industry chain to break the information islands and then enables them to achieve interconnection , accurate order distribution and real-time data sharing.

This way it forms a large synergy of the whole industry chain, and provides high-quality electronic products for global electronic brands while maintaining the Quality and on-time supply chain services.

Advantages of OEM Service

- Help customers complete integrated R&D tasks faster and better.

- Achieve rapid and sustainable development.

- Deliver stable, reliable and efficient products.